3D Printing & 3D Scanning>>>Computer & Office

Brand Name AOKIN

Origin CN(Origin)

Item Type Module

Model Number 3D Printer Kit

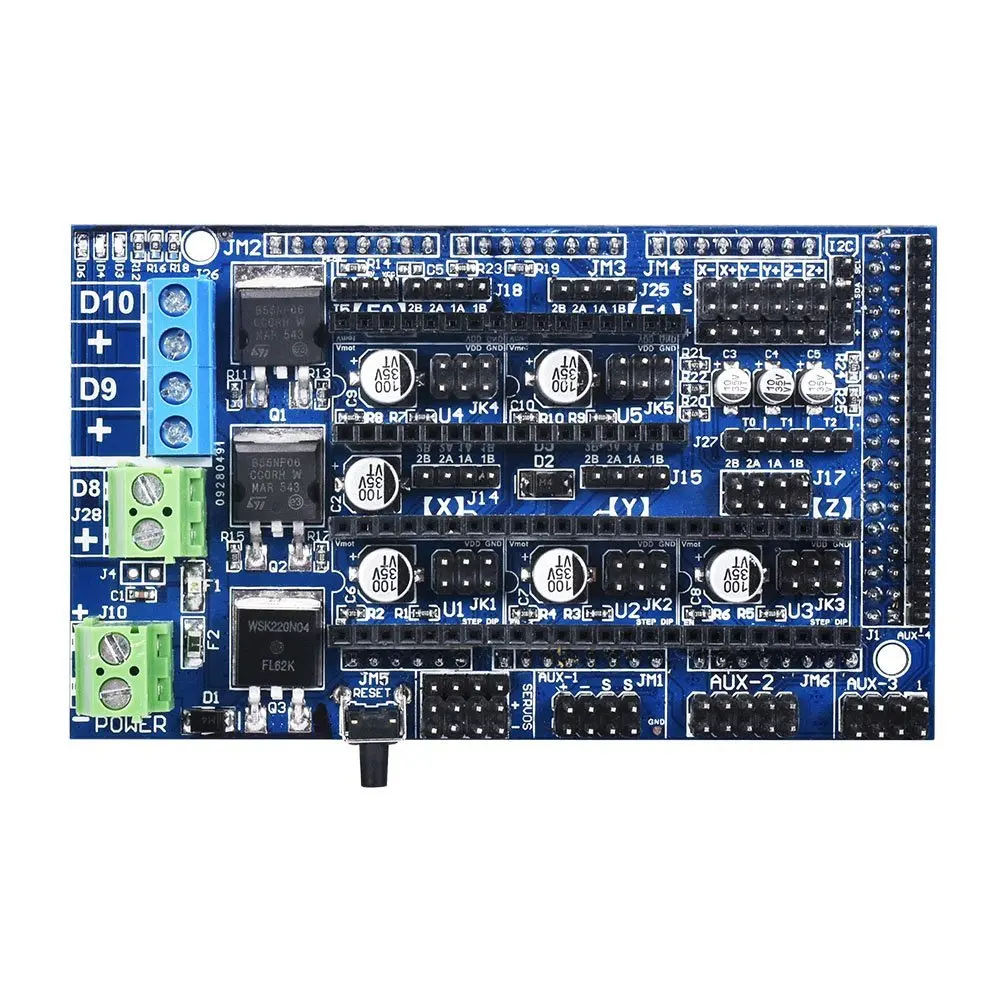

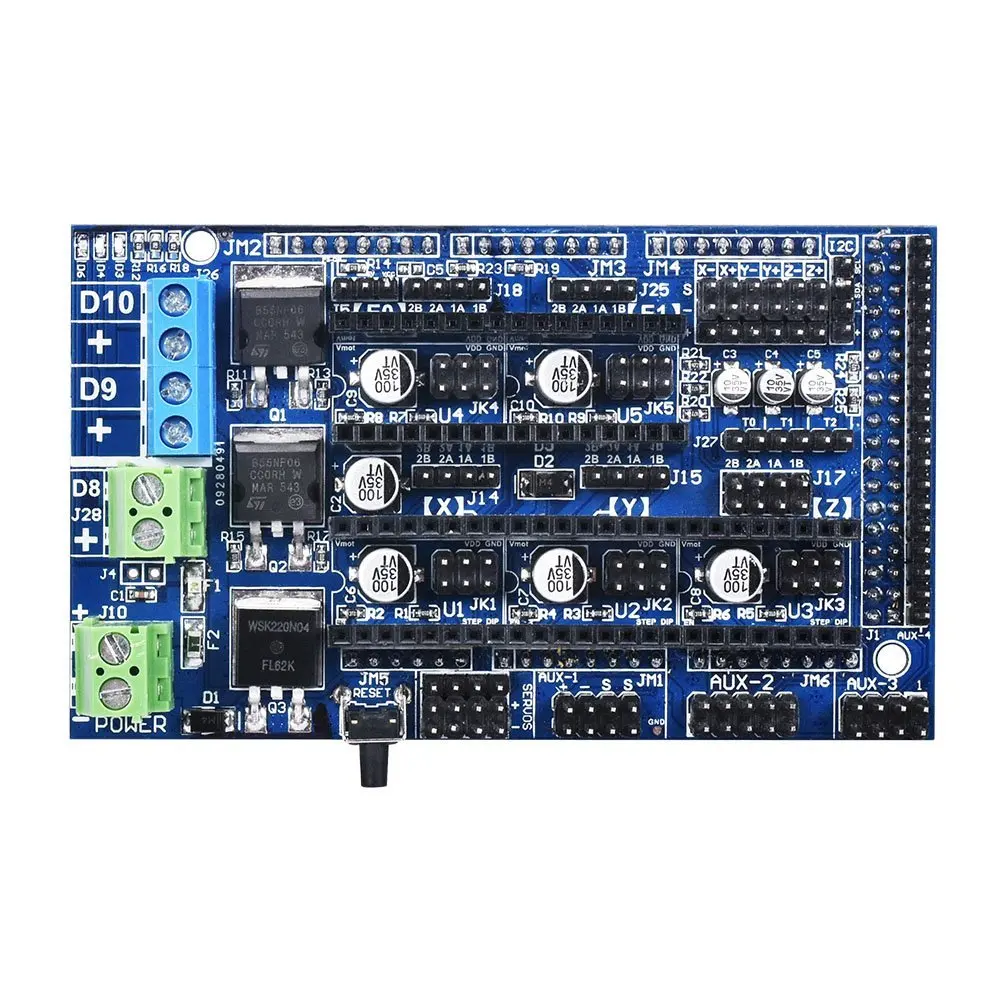

Ramps 1.4 Kit Ramps 1.6

Mega 2560 r3 Heatbed MK2B

12864 LCD DRV8825

DRV8825 Mechanical Switch

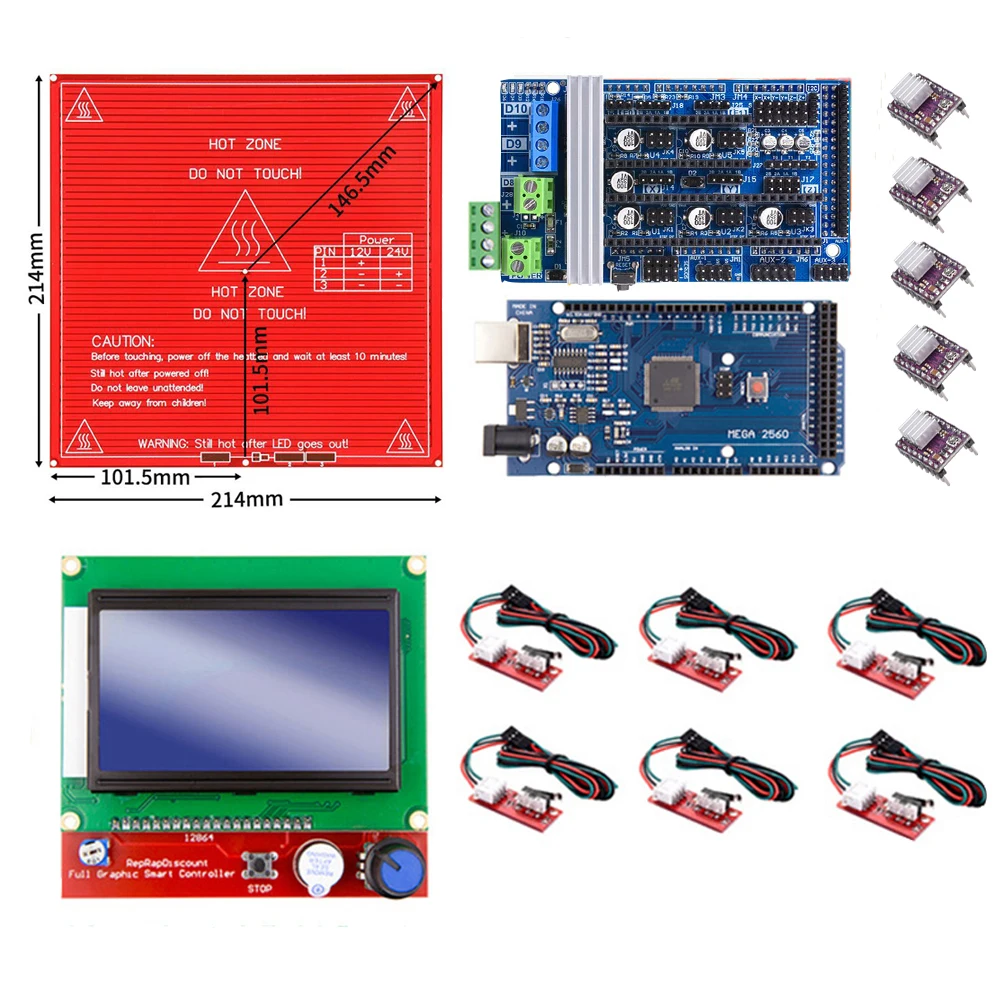

MK2B Heatbed

MK2B is the latest and the best type of heatbed money can buy as of today. 100% compatible

with all Prusa and Mendel 3d printer variants.

Color: Red

Size: 214mm x 214mm

Etching: 35um copper

Laminate: FR4 1.6mm

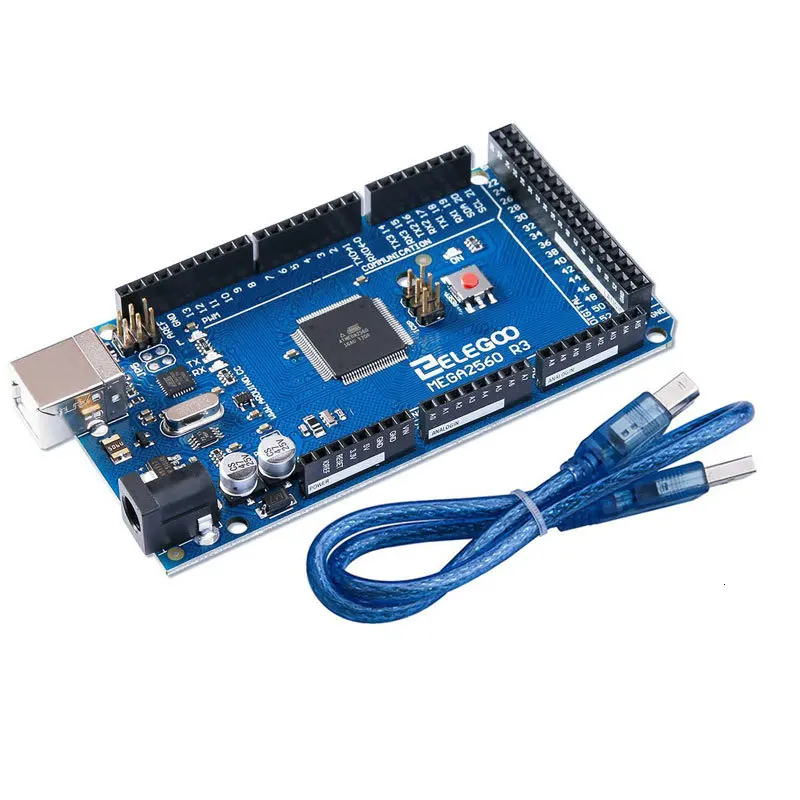

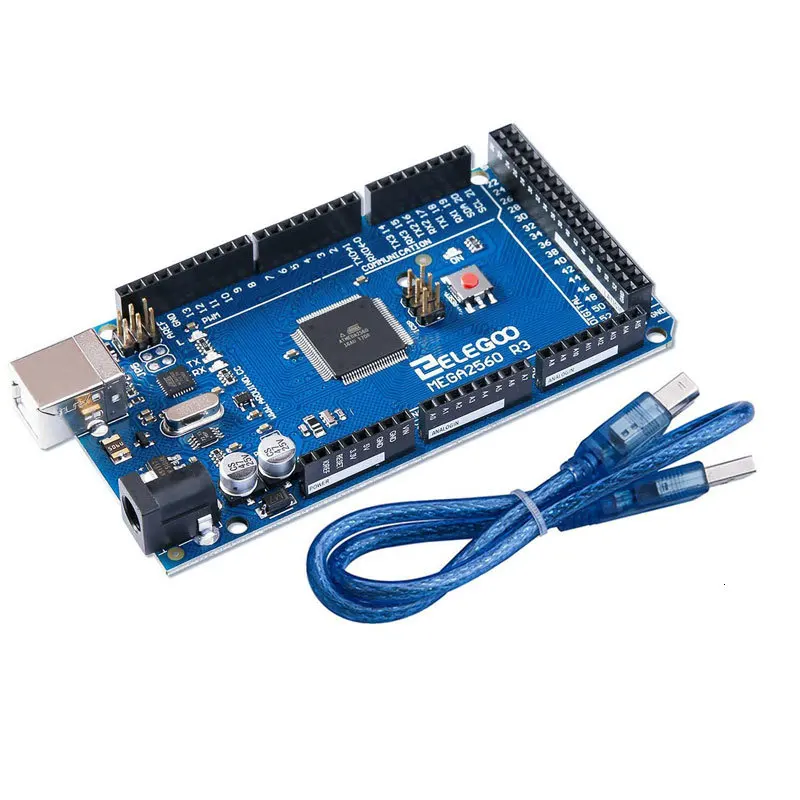

Mega 2560

Microcontroller : ATmega2560

Operating Voltage : 5V

Input Voltage (recommended) : 7-12V

Input Voltage (limits) : 6-20V

Digital I/O Pins : 54 (of which 14 provide PWM output)

Analog Input Pins : 16

DC Current per I/O Pin : 40 mA

DC Current for 3.3V Pin : 50 mA

Flash Memory : 256 KB of which 4 KB used by bootloader

SRAM : 8 KB

EEPROM : 4 KB

12864 LCD Controller Board

3D printers use LCD control panel, are ramps extension accessories. LCD control panel through

which you can achieve spooling is the 3D model Gcode files are copied to the SD card, and then

print the file via the LCD control panel. This version is an upgraded version of reprap smart controller.

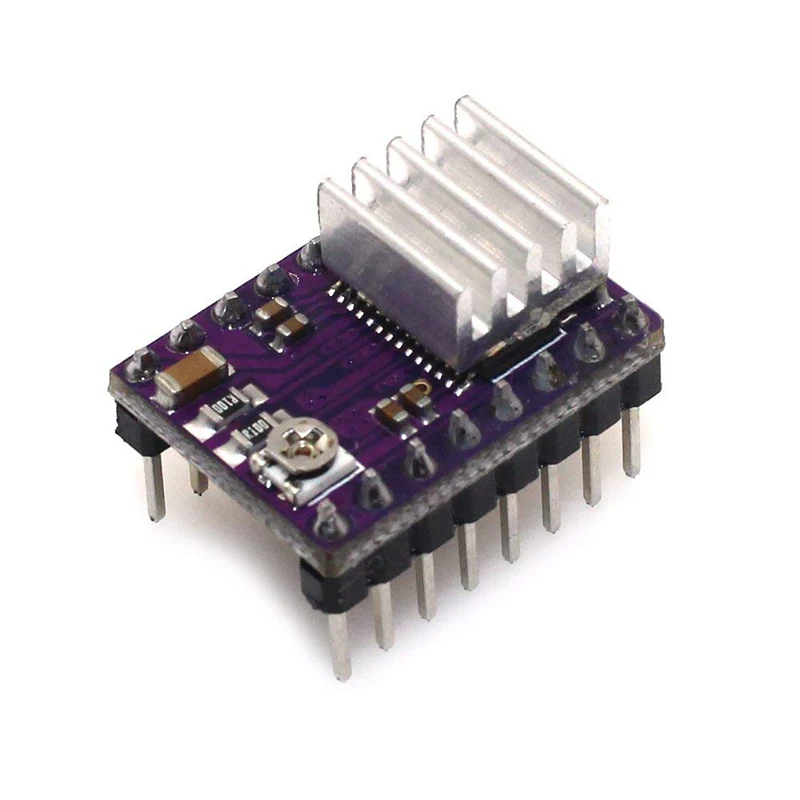

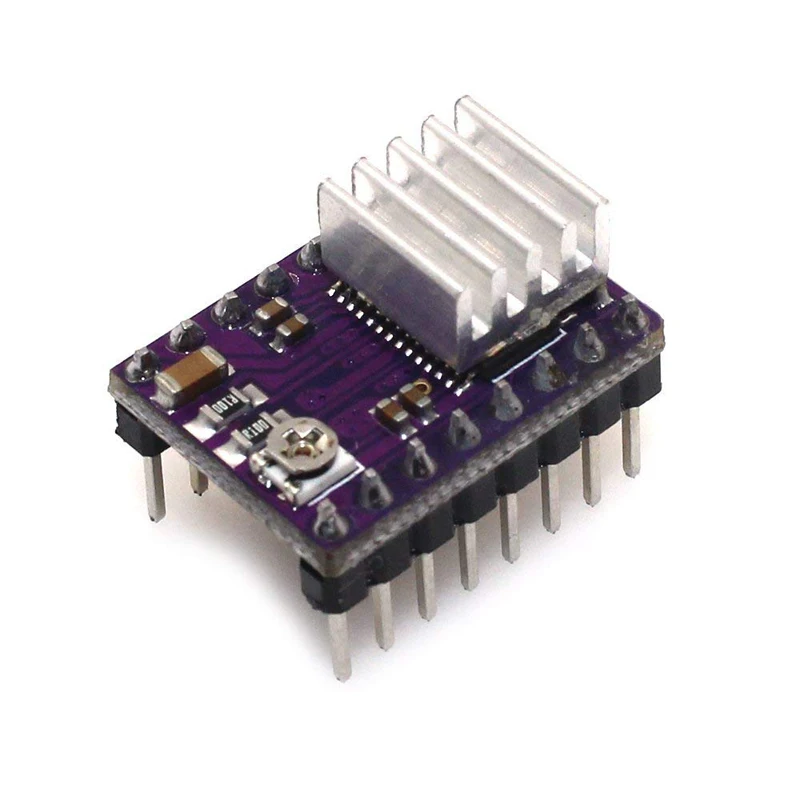

DRV8825 Stepper Motor Driver

The DRV8825 stepper motor driver carrier board TI DRV8825 micro bipolar stepper motor drive is

a breakthrough. The module has a pinout and interface with our A4988 stepper motor driver carrier

is almost the same, so it can be used as a better performance of the pull-down menu board

replacement in many applications. DRV8825 features an adjustable current limit, overcurrent and

overtemperature protection, six micro-resolution (down 1/32-step). It uses 8.2 - 45 V, can provide

up to about 1.5 per phase no heat sink or forced air flow (rated up to 2.2 per volume sufficient

additional cooling).

A simple steps and direction control interface

Six different steps resolutions: full step, half step, 1/4-step1/8-step1/16-step, 1/32-step

CAN interface directly with 3.3 V and 5 V systems

Over-temperature thermal shutdown, overcurrent shutdown, undervoltage lockout

Short to ground short circuit load protection

4 Layer 2 oz copper PCB, in order to improve heat dissipation

Exposed solder ground below the bottom of the driver IC on the printed circuit board pad

Module size, pin and interface matching A4988 stepper motor driver operators in many ways

Adjustable current control lets you set a potentiometer, which lets you use the stepper motor's

rated voltage or more, in order to achieve a higher rate of maximum output current step

Intelligent chopping control automatically selects the correct current decay mode (fast decay or

slow decay)

Maximum 45 V supply voltage

Built-in voltage regulator (the need for any external logic supply voltage)

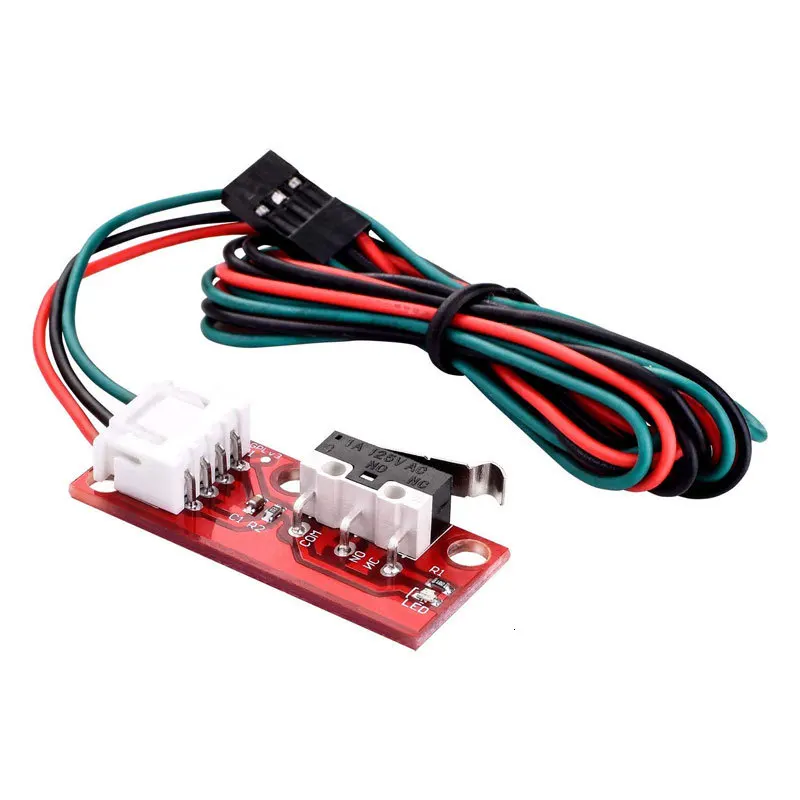

Limit Switch Endstop

Quality switching elements.

Customized high quality connection, using 22AWG wire, copper wire inside is very thick, can be

resistant to current 2A, 300V voltage. An insulating layer over a wide range of temperatures, up to

80 degrees. Is the common connection of thin copper wire can not match. Not easy to pull off, plug

it convenient, for ease of use, plug the other side to do the one, you can use the direct plug.

Red line connecting VCC (ramps of +)

Connect the black wire GND (ramps of -)

Green Line connection SIGNAL (ramps in s)

tips: Under normal circumstances, the system must be configured to at least three mechanical switches.

Pros: Easy to install, the more common styles.

Disadvantages: easy to wear and tear of mechanical parts, service life is shorter

Package included:

1 X mk2b heatbed

1 X MEGA 2560

1 X 12864 LCD Controler Board

1 X Ramps 1.6

6 X Limit Switch

5 X Drv8825 Stepper Motor Driver